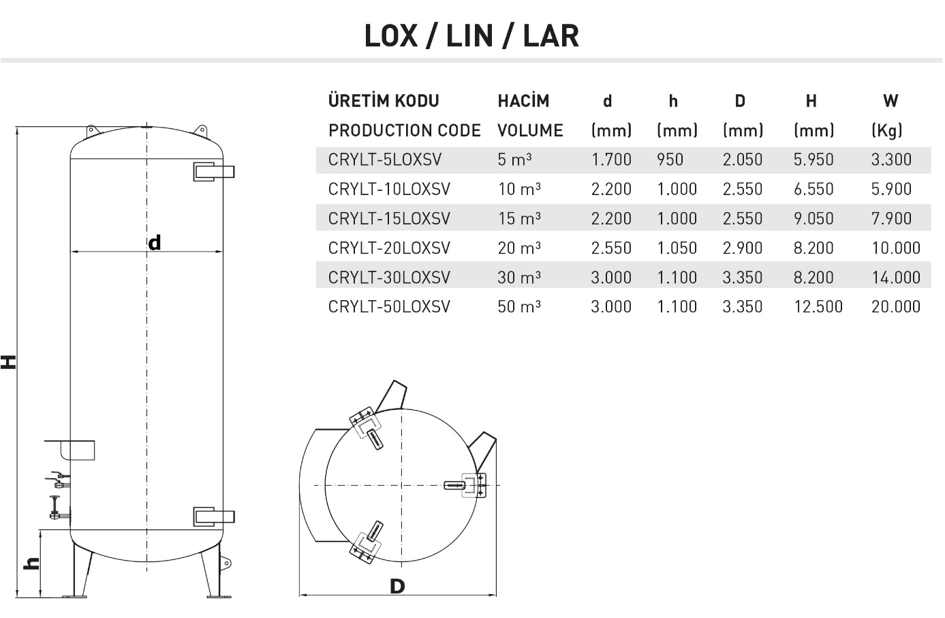

LIQUID OXYGEN TANK

Temperatures between -150°C and absolute zero (-273°C) are also defined as cryogenic temperatures. These low temperatures; It is also used in the liquefaction of gases such as oxygen, hydrogen, helium, argon and nitrogen. Cryogenic tanks are produced to transport and store gases in the liquid phase - liquefied natural gas (LNG), liquefied nitrogen (LIN), liquefied argon (LAR), liquefied oxygen (LOX).

The tanks are designed as an inner tank and an outer envelope to protect the phase of the liquefied gas inside. 304L quality stainless steel material is used for the inner tanks and carbon steel material is used for the outer tank. After the main tank is placed in an outer tank, the volume between the two tanks is filled with cryogenic perlite aggregate and heat transfer is prevented by vacuuming up to the theoretical absolute vacuum value. Thus, as long as cryogenic storage tanks are used, high performance is ensured, which ensures that liquefied gases remain ungasified for a longer period of time, as well as low maintenance costs. Super insulation thermal insulation application can be made depending on the project need and demand.

The maximum working pressure of cryogenic liquefied gas storage tanks ranges from 2 to 37 bar, depending on where the tank is to be used.

Our experience and knowledge in design enable us to offer high quality, robust and reliable solutions to our customers. Extremely rigorous and detailed testing is an essential part of maintaining the high performance and quality of Cryolet cryogenic tanks.

Following the approval of the project calculations, the tests required by the standards such as material quality, non-destructive testing, impermeability tests are carried out by the third party inspection organization at all manufacturing stages and the results are filed. The labels on the tank contain all the features of the tank and the approval of the quality certificate. The user is given technical training on the operation of the tank by Cryolet engineers. In addition, training information, usage directives and quality certificate approvals are presented to the user with a file.

In addition to our productions in accordance with AD MERKBLATT CODE 2000, EN 13458, EN 13530, ADR 2013 and ASME Sec VIII Div1 standards as a design standard, designs can also be made in different local standards in line with customer demands.

Steel oxygen cylinders contain breathable oxygen. Because this oxygen is high pressure, it cannot be used directly. A manometer is connected to the tube for the use of oxygen. The filling amount of the tube can be monitored via the manometer. After the manometer is connected so that there is no leakage, the valve of the tube is opened and oxygen flow is provided. There are varieties of aluminum and steel according to the material of the tube.

EVAPORATOR

EVAPORATORHeat Cycle Systems

One of the important links of the energy systems chain is heat conversion systems. We produce heat conversion systems that are used for different purposes, such as heat exchangers (heat exchangers) and evaporators (evaporators).

A heat exchanger or heat exchanger is a device that allows two or more fluids at different temperatures to transfer their heat from one to the other without mixing (contacting). In general, the fluids are separated from each other by a heat transfer surface and their mixing with each other is thus prevented.

Its usage areas are very wide. It is widely used in process, petrochemical, power plants, building heating cooling, air handling units, refrigeration, shipbuilding, papermaking, wastewater, heat recovery, and other industrial sectors.

Evaporators (evaporators) are used together with cryogenic tanks for the evaporation of Carbon Dioxide (CO2), Oxygen (O), Nitrogen (N), Argon (Ar) and other gaseous liquids that are transported and stored as liquefied. The ambient temperature meets the required energy and the cryogenic liquid passing through the evaporator evaporates, passes into the gas phase again and enters into use.

Our evaporators are manufactured by serial and parallel connection of finned pipes produced from special aluminum alloy by extrusion method. This type of evaporator, which can provide high heat transfer thanks to the area created by the fins open to interaction with the environment, is sufficient to provide the required gas capacity in many applications.

Tank pressurizers of different capacities, low and high pressure tanks, to meet the need by sensitively evaluating the factors that directly affect the evaporator performance, such as the amount of fluid, operating time, ambient temperature, relative humidity, freezing time, geographical height of the region where the evaporator operates, wind, solar radiation, operating pressure, as design parameters. manufactures pressure evaporators.